A power station (also referred to as a generating station, power plant, powerhouse, or generating plant) is an industrial facility for the generation of electric power. Most power stations contain one or more generators, a rotating machine that converts mechanical power into electrical power. The relative motion between a magnetic field and a conductor creates an electrical current. Most power stations in the world burn fossil fuels such as coal, oil, and natural gas to generate electricity. Others use nuclear power, but there is an increasing use of cleaner renewable sources such as solar, wind, wave and hydroelectric.

Coal

is first milled to a fine powder, which increases the surface area

and allows it to burn more quickly. In these pulverised coal

combustion systems, the powdered coal is blown into the combustion

chamber of a boiler where it is burnt at high temperature. The hot

gases and heat energy produced converts water – in tubes lining the

boiler – into steam. The high pressure steam is passed into a

turbine containing thousands of propeller-like blades. The steam

pushes these blades causing the turbine shaft to rotate at high

speed. A generator is mounted at one end of the turbine shaft and

consists of carefully wound wire coils. Electricity is generated when

these are rapidly rotated in a strong magnetic field. After passing

through the turbine, the steam is condensed and returned to the

boiler to be heated once again. The electricity generated is

transformed into the higher voltages (up to 400,000 volts) used for

economic, efficient transmission via power line grids. When it nears

the point of consumption, such as our homes, the electricity is

transformed down to the safer 100-250 voltage systems used in the

domestic market.

A

magneto

is

an electrical

generator

that

uses permanent

magnets

to produce alternating

current.

Unlike a dynamo,

there is no commutator

and

so they cannot produce direct

current.

They are categorised as a form of alternator,

although they are usually regarded as distinct from most other

alternators, which use field

coils

rather

than permanent magnets. Magnetos

have advantages of simplicity and reliability, but are inefficient

owing to the weak magnetic

flux

available

from their permanent magnets. This restricted their use for

high-power applications. Some magnetos did find use as telephone

magnetos

in

early telephones,

particularly for ringing. The most common application for magnetos

was as an ignition

magneto,

in spark-ignition petrol

engines,

ranging from early cars to aircraft (for reliability) and small

engines

such

as chainsaws.

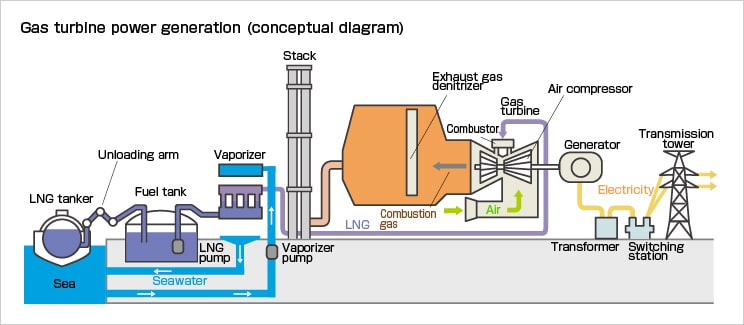

The use of gas turbines for generating electricity dates back to 1939. Today, gas turbines are one of the most widely-used power generating technologies. Gas turbines are a type of internal combustion engine in which burning of an air-fuel mixture produces hot gases that spin a turbine to produce power. It is the production of hot gas during fuel combustion, not the fuel itself that the gives gas turbines the name. Gas turbines can utilize a variety of fuels, including natural gas, fuel oils, and synthetic fuels. Combustion occurs continuously in gas turbines, as opposed to reciprocating internal combustion engines, in which combustion occurs intermittently.

Diesel

generators

A diesel

generator is

the combination of a diesel

engine

with

an electric

generator

(often

an alternator)

to generate electrical

energy.

. A diesel compression-ignition engine often is designed to run on

fuel oil, but some types are adapted for other liquid fuels or

natural

gas.

Diesel

generating sets are used in places without connection to a power

grid,

or as emergency power-supply if the grid fails, as well as for more

complex applications such as peak-lopping, grid support and export

to the power grid.

In

South Africa it costs about R2.35 per kilowatt hour to generate

electricity with diesel generators as opposed to less than 50 cents

per kilowatt hour to generate power at coal power stations.

Powerships

The

Karadeniz

Energy Group developed its

“Power of Friendship” project for countries in the Middle East,

Africa and Asia.Some African countries, notably Ghana, get electricity from Powerships, which are essentially floating power stations.According to Karadeniz its power ships are “high technology floating power plants designed and constructed to fulfil the urgent electricity needs of the countries through rental contracts or power purchase agreements (PPA)”. Power ships are delivered to the client countries as a complete power plant ready to operate immediately. Power ship capacities range from 45MW to 500MW, and are delivered between 60 days and 180 days after ordering to provide medium-term solutions with contracts of between 2 years to 5 years.

Biomass

electricity

Biomass

is biological

material

derived

from living, or recently living organisms. It most often refers to

plants or plant-based materials . As

an energy source, biomass can either be used directly via combustion

to produce heat, or indirectly after converting it to various forms

of biofuel

like

methane gas or transportation fuels like ethanol

and

biodiesel.

The

main contributors of waste

energy

are

municipal

solid waste,

manufacturing

waste,

and landfill

gas.

Energy derived from biomass is projected to be the largest

non-hydroelectric renewable resource of electricity in the US between

2000 and 2020.

The

biomass power generating industry in the United States, which

consists of approximately 11,000 MW

of

summer operating capacity actively supplying power to the grid,

produces about 1.4 percent of the U.S. electricity supply.

An

engine-generator

is the combination of an electrical

generator

and

an engine

mounted

together to form a single piece of equipment. This combination is

also called an engine-generator set or a gen-set. In many contexts,

the engine is taken for granted and the combined unit is simply

called a generator. In

addition to the engine and generator, engine-generators generally

include a fuel supply, a

constant

engine speed regulator (governor) and a generator voltage

regulator,

cooling and exhaust systems, and lubrication system.

Engine-generators

are available in a wide range of power ratings. Regardless of the

size, generators may run on gasoline,

diesel,

natural

gas,

propane,

bio-diesel,

sewage

gas

or

hydrogen.

The

smaller units are built to use gasoline (petrol) as a fuel, and the

larger ones have various fuel types, including diesel, natural gas

and propane (liquid or gas).

A

dynamo

is

an electrical

generator

that

produces direct

current

with

the use of a commutator.

A

commutator is the moving part of a rotary electrical

switch

in

certain types of electric

motors

and

electrical

generators

that

periodically reverses the current

direction

between the rotor and the external circuit. Dynamos

were the first electrical generators capable of delivering power for

industry, and the foundation upon which many other later

electric-power conversion devices were based, including the electric

motor,

the alternating-current alternator,

and the rotary

converter. Today,

the simpler alternator dominates large scale power generation, for

efficiency, reliability and cost reasons. A dynamo has the

disadvantages of a mechanical commutator. Also, converting

alternating to direct current using power rectification devices

(vacuum tube or more recently solid

state)

is effective and usually economic. An

alternator

is

an electrical

generator

that

converts mechanical energy to electrical energy in the form of

alternating

current.

For

reasons of cost and simplicity, most alternators use a rotating

magnetic

field

with

a stationary armature.

Image: http://poradu.pp.ua

Fuel

cell generated electricity

A

fuel

cell is

a device that converts the chemical

energy

from

a fuel into electricity through a chemical reaction with oxygen or

another oxidizing

agent.

F;uel

cells are different from batteries

in

that they require a continuous source of fuel and oxygen/air to

sustain the chemical reaction whereas in a battery the chemicals

present in the battery react with each other to generate an

electromotive

force

.

Fuel cells can produce electricity continuously for as long as these

inputs are supplied. There are many types of fuel cells, but they

all consist of an anode,

a cathode

and

an electrolyte

that

allows charges to move between the two sides of the fuel cell.

Electrons are drawn from the anode to the cathode through an external

circuit, producing direct

current

electricity.

As the main difference among fuel cell types is the electrolyte. In

addition to electricity, fuel cells produce water, heat and,

depending on the fuel source, very small amounts of nitrogen

dioxide

and

other emissions.

Fuel

cells are used for primary and backup power for commercial,

industrial and residential buildings and in remote or inaccessible

areas. They are also used to power fuel-cell

vehicles,

including forklifts, automobiles, buses, boats, motorcycles and

submarines.

Source: Wikipedia

Manufacturers

of fuel cells and fuel cell products

A list

of 200 companies and organizatons in

the fuel cell industry, from developers to component manufacturers to

hydrogen suppliers and system integrators, can

be ECR

International found

on the Fuel

Cells Organization's

website.

Polymer

Electrolyte Membrane or Proton-Exchange Membrane (PEM) fuel cell.

Alkaline

Fuel Cells (AFCs) have a solution of

potassium hydroxide in water as an

electrolyte which allows the precious metal

catalyst of PEM fuel cells to be replaced

by a variety of non-precious metals.

Molten

Carbonate fuel cells (MCFCs) use a high

temperature salt mixture suspended In

an inert ceramic matrix as an electrolyte.

Solid

Oxide Fuel Cells (SOFCs) use a solidceramic

as the electrolyte.

The

Chamber of Mines of South Africa has installed a 100kW base load

platinum fuel cell which has been running well since December 18,

2014.

Fuel cell electric vehicles now have comparable ranges to

conventional vehicles (>600 kms) and only a three minute filling

time (compares to 100km range for a pure electric vehicle and 3-9

hour charging time for the batteries) and which emits no pollutants

during driving. These FCEV’s, like the Toyota Mirai are now being

sold in Japan and California and could revolutionise automotive

travel. The Mirai can also be used as a back-up generator for home

use (during load-shedding).

Toyota

Mirai

cutaway showing the electric

traction motor and

power control unit in the front, the fuel

cell

stack

in the middle, and the nickel-metal

hydride

traction

rechargeable

battery

above

the hydrogen

storage tanks

in

the rear.

Nuclear

power stations

Image: http://www.ijrte.org

A nuclear power plant is a thermal power station in which the heat source is a nuclear reactor. A nuclear reactor is a device to initiate and control a sustained nuclear chain reaction. Nuclear reactors usually rely on uranium to fuel the chain reaction. As is typical in all conventional thermal power stations the heat is used to generate steam which drives steam turbines connected to an electric generator which produces electricity. As of 23 April 2014, the International Atomic Emergy Agency reported that there are 435 nuclear power reactors in operation operating in 31 countries. Nuclear power plants are usually considered to be base load stations, since fuel is a small part of the cost of production. Since nuclear fission creates radioactivity, the reactor core is surrounded by a protective shield. This containment absorbs radiation and prevents radioactive material from being released into the environment. In addition, many reactors are equipped with a dome of concrete to protect the reactor against both internal casualties and external impacts. The amount of free energy contained in nuclear fuel is millions of times the amount of free energy contained in a similar mass of chemical fuel such as gasoline, making nuclear fission a very dense source of energy. Nuclear fission is the main process generating nuclear energy. Nuclear

currently makes up 11% of the global energy mix, according to the

World Nuclear Association.

Nuclear betavoltaic electricity generation are generators of electric current, in effect a form of battery, which use energy from a radioactive source emitting beta particles (electrons). The terms atomic battery, nuclear battery, tritium battery and radioisotope generator are used to describe a device which uses energy from the decay of a radioactive isotope to generate electricity. Like nuclear reactors they generate electricity from atomic energy, but differ in that they do not use a chain reaction. Compared to other batteries they are very costly, but have extremely long life and high energy density, and so they are mainly used as power sources for equipment that must operate unattended for long periods of time, such as spacecraft, pacemakers, underwater systems and automated scientific stations in remote parts of the world. Recent progress has prompted some to suggest using betavoltaics to trickle-charge conventional batteries in consumer devices, such as cell phones and laptop computers. A common source used is the hydrogen isotope, tritium. Unlike most nuclear power sources, which use nuclear radiation to generate heat, which then is used to generate electricity (thermoelectric and thermionic sources), betavoltaics use a non-thermal conversion process; converting the electron-hole pairs produced by the ionization trail of beta particles traversing a semiconductor.

Manufacturers of betavoltaic batteries

- City Labs Inc. is a manufacturer of long-life Tritium betavoltaic batteries for microelectronics, sensors, and other small devices.

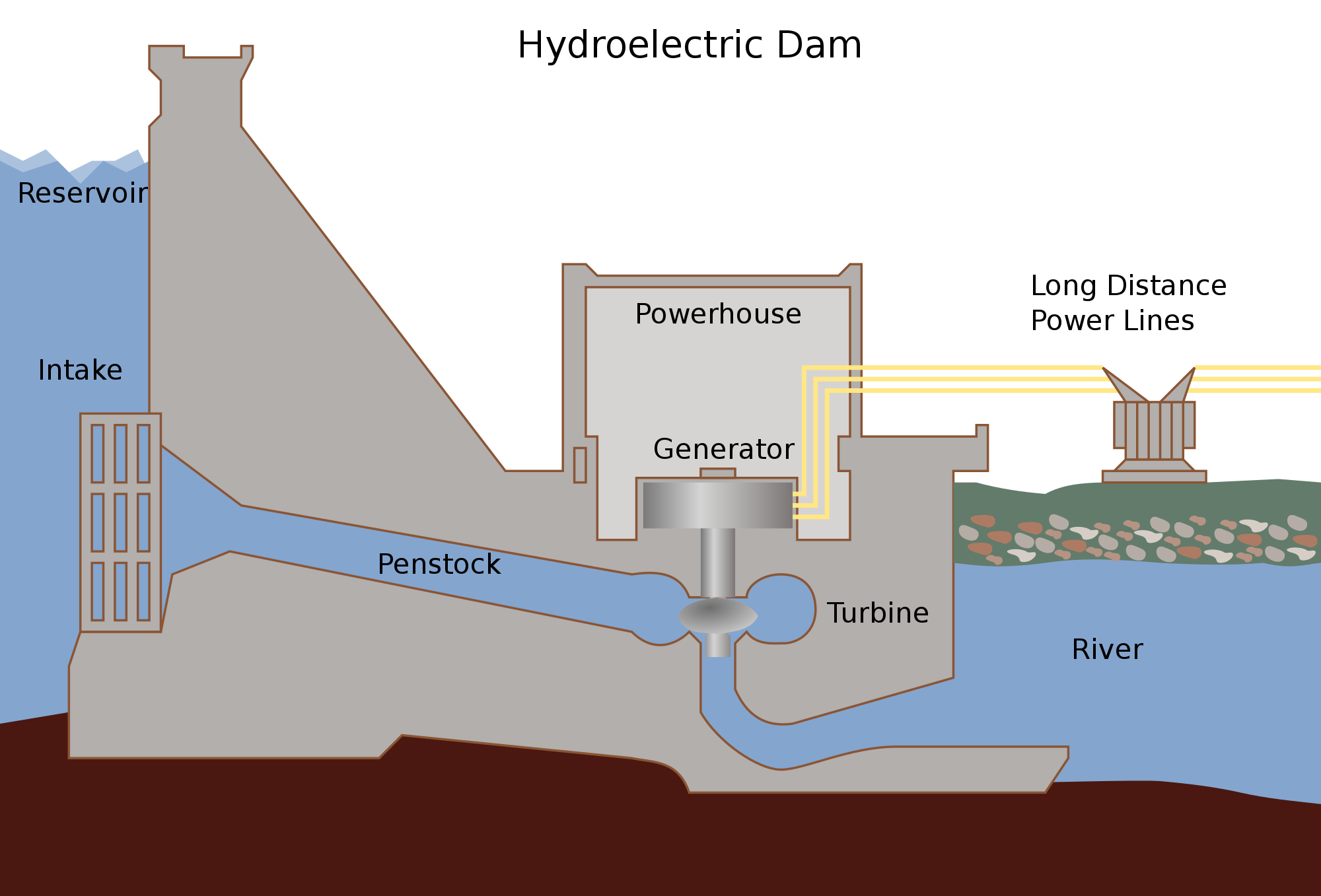

Hydroelectric power stations

Source: http://www.sunyjcc.edu

Hydroelectricity is

the term referring to electricity generated

by hydropower;

the production of electrical power through the use of the

gravitational force of falling or flowing water. It is the most

widely used form of renewable

energy,

accounting for 16 percent of global electricity generation

Hydropower

is produced in 150 countries, with the Asia-Pacific region generating

32 percent of global hydropower in 2010. China is the largest

hydroelectricity producer with around 17 percent of domestic

electricity use.

Source: http://www.cgee.org.br

The

cost of hydroelectricity is relatively low, making it a competitive

source of renewable electricity. It is also a flexible source of

electricity since the amount produced by the station can be changed

up or down very quickly to adapt to changing energy demands. However,

damming interrupts the flow of rivers and can harm local ecosystems,

and building large dams and reservoirs often involves displacing

people and wildlife.

Once

a hydroelectric complex is constructed, the project produces no

direct waste, and has a considerably lower output level of

the greenhouse

gas carbon

dioxide

(CO2)

than fossil

fuel

powered

energy plants.

Micro

hydro is

a type of hydroelectric

power that

typically produces up to 100 kW of electricity using

the natural flow of water. These installations can provide power to

an isolated home or small community.

Lucid Energy's

LucidPipe™ Power System harnesses the untapped energy potential of

moving water in

pipelines to

produce electricity.

Pumped-storage

hydroelectricity is

a type of hydroelectric energy

storage used

by electric

power systems for load

balancing.

The method stores energy in the form of gravitational

potential energy of

water, pumped from a lower elevation reservoir to a higher

elevation. Low-cost off-peak electric power is used to run the pumps.

During periods of high electrical demand, the stored water is

released through turbines to

produce electric power. Although the losses of the pumping process

makes the plant a net consumer of energy overall, the system

increases revenue by

selling more electricity during periods of peak

demand,

when electricity prices are highest.

Wave power electricity

Source: http://www.mpoweruk.com/hydro_power.htm

Wave power is the transport of energy by ocean surface waves, and the capture of that energy to do useful work – for example, electricity generation, water desalination, or the pumping of water (into reservoirs). A machine able to exploit wave power is generally known as a wave energy converter (WEC). Wave power is distinct from the diurnal flux of tidal power and the steady gyre of ocean currents.Wave-power generation is not currently a widely employed commercial technology, although there have been attempts to use it since at least 1890.In 2008, the first experimental wave farm was opened in Portugal, at the Aguçadoura Wave Farm..The major competitor of wave power is offshore wind power.

The

UK Energy Ministry approved planning and construction is expected to

start sometime in 2017 of

a six-mile-long

barrier wall that will enclose a huge amount of water in an

artificial “tidal lagoon”. This planned power plant in Wales will

use the rise and fall of ocean tides to generate enough electricity.

420 gigawatt hours per year, to power 155,000 homes for 120 years.

Osmotic power

Osmotic

power or

salinity

gradient power is

the energy available from the difference in the salt concentration

between seawater

and

river

water.

Two practical methods for this are reverse

electrodialysis

(RED)

and pressure

retarded osmosis

(PRO).

Both processes rely on osmosis

with

ion specific membranes.

The key waste product is brackish

water.

This by product is the result of natural forces that are being

harnessed: the flow of fresh water into seas that are made up of salt

water. The technologies have been confirmed in laboratory conditions.

They are being developed into commercial use in the Netherlands (RED)

and Norway (PRO). The cost of the membrane has been an obstacle. A

new, lower cost membrane, based on an electrically modified

polyethylene

plastic,

made it fit for potential commercial use. Other methods have been

proposed and are currently under development. Among them, a method

based on electric

double-layer capacitor

technology.and

a method based on vapor

pressure

difference.

Source: http://www.dutchwatersector.com

Solar power generated electricity

Photovoltaic

(PV)

is the direct conversion of light into electricity and

a

method of converting solar energy into direct current electricity

using semiconducting materials that exhibit the photovoltaic

effect

A

solar cell,

or photovoltaic

cell,

is an electrical device that converts the energy of light

directly

into electricity

by

the photovoltaic

effect,

which is a physical

and

chemical

phenomenon.

Solar cells are the building blocks of photovoltaic modules,

otherwise known as solar

panels.

A

solar

panel

refers to a photovoltaics

(PV)

module,

a set of solar photovoltaics

modules

electrically connected and mounted on a supporting structure. A PV

module

is

a packaged, connected assembly of solar

cells.

Solar panels can be used as a component of a larger photovoltaic

system

to generate

and supply electricity

in

commercial and residential applications. Each module is rated by its

DC

output

power under standard test conditions, and typically ranges from100 to

320 watts. Concentrated

solar power (also

called concentrating

solar power,

concentrated

solar thermal,

and CSP)

systems generate solar

power

by

using mirrors or lenses to concentrate a large area of sunlight, or

solar

thermal energy,

onto a small area. Electricity

is

generated when the concentrated light is converted to heat, which

drives a heat

engine

(usually

a steam

turbine)

connected

to

an electrical power

generator

or

powers a thermochemical reaction (experimental as of 2013).

Geothermal

generated

electricity

Geothermal electricity is electricity generated to geothermal energy. Technologies in use include dry steam power stations, flash steam power stations and binary cycle power stations. Dry steam stations are the simplest and oldest design. They directly use geothermal steam of 150°C or greater to turn turbines. Flash steam stations pull deep, high-pressure hot water into lower-pressure tanks and use the resulting flashed steam to drive turbines. They require fluid temperatures of at least 180°C, usually more. Geothermal electricity generation is currently used in 24 countries, while geothermal heating is in use in 70 countries.

Scientists

at Stanford University

have improved the efficiency of a revolutionary solar cell by around

100 times. Unlike standard photovoltaic cells, which only capture

light energy, Stanford’s new device captures both light and

heat,

potentially boosting solar cell efficiency towards 60% — way beyond

the 30-40% limit of traditional silicon photovoltaic solar cells.

The

Solar Thermal Energy Research Group (STERG) at Stellenbosch University has been developing a unique South African CSP technology.

CSP is able to provide dispatchable, clean energy at utility scale,

with the added benefit of high localisation potential and

socio-economic beneficiation. In early 2014 the team won a grant from

the Technology Innovation Agency to showcase the technology in a

100kW pilot facility. The technology takes a simple and fresh

approach to overcome the challenges that are currently faced in

heliostat fields.

Google's Project Sunroof computes how much sunlight hits your roof in a year. It takes

into account:

- Google's database of aerial imagery and maps

- 3D modeling of your roof

- Shadows cast by nearby structures and trees

- All possible sun positions over the course of a year

- Historical cloud and temperature patterns that might affect solar energy production

Rawlemon has

created a spherical sun power generator prototype called the

beta.ray. The

technology will combine spherical geometry principles with a dual

axis tracking system, allowing twice the yield of a conventional

solar panel in

a much smaller surface area. The futuristic design is fully

rotational and is suitable for inclined surfaces, walls of buildings,

and anywhere with access to the sky. It can even be used as an

electric

car charging

station.

Manufacturers

of solar panels.

- Trina Solar (China) is a global leader in photovoltaic modules, solutions and services. Founded in 1997 as a PV system integrator, Trina Solar today drives smart energy together with installers, distributors, utilities and developers worldwide.

- Yingli Green Energy (China)

- Jinko Solar (China)

- JA Solar (China)

- Sharp Solar ( Japan)

- First Solar (USA) is an American photovoltaic (PV) manufacturer of rigid thin film modules, or solar panels, and a provider of utility-scale PV power plants and supporting services that include finance, construction, maintenance and end-of-life panel recycling.

- Hanwha SolarOne (China)

- SunPower (USA) and Kyocera (Japan)

- SolarCity, the company co-founded by Elon Musk, now produces the world's most efficient rooftop solar panels with a module efficiency of just over 22 percent. SolarCity CEO Lyndon Rive said that the company is shooting for a cost of around 55 cents per watt. It plans to build the 360 watt panels in its 1 GW solar panel plant in Buffalo, New York, set to open in 2016.

Source: http://www.alternative-energy-news

Wind

power generated

electricity

Wind

power is

extracted from air

flow

using

wind

turbines

to

produce electrical

power.

A

generator inside the nacelle (a housing at the top of a wind turbine

mast for the generating components, including the gearbox, drive

train, and brake assembly) converts the wind power into electricity.

Wind

power as an alternative to fossil

fuels,

is plentiful, renewable,

widely distributed, clean,

produces no greenhouse

gas

emissions

during operation, and uses little land.

The

net effects

on the environment

are

generally less problematic than those from non-renewable power

sources. Large

wind

farms

can

consist of hundreds of individual wind turbines which are connected

to the electric

power.transmission

network.

Gansu

Wind Farm,

the largest wind farm in the world, has several thousands of

turbines. Onshore wind is an inexpensive source of electricity,

competitive with or in many places cheaper than coal, gas or fossil

fuel plants. Offshore wind is steadier and stronger than on land, and

offshore farms have less visual impact, but construction and

maintenance costs are considerably higher. Small onshore wind farms

can feed some energy into the grid or provide electricity to isolated

off-grid locations.

Wind

power is very consistent from year to year but has significant

variation over shorter time scales. It is therefore used in

conjunction with other sources to give a reliable supply.

As

of 2014, Denmark

had been generating

around

40% of its electricity from wind

and

at least

83 other countries around the world are using wind power to supply

their electricity grids.

Wind

power capacity has expanded rapidly to 336 GW

in

June 2014, and wind energy production was around 4% of total

worldwide electricity usage.

South

Africa increased its installed wind-energy capacity to above 1 GW in

2015,

new Global Wind Energy Council (GWEC) figures show, making it the

largest wind-energy producer in Africa, followed by Morocco, whose

installed capacity stood at 787 MW in 2015. South Africa’s wind

growth has been stimulated primarily by government’s Renewable

Energy Independent Power Producer Procurement Programme, through

which 6 300 MW of renewable-energy capacity has been procured since

2011. Prices for wind have also fallen from R142c/kWh in the first

bid window in 2011, to 65c/kWh in the fourth bid window. Print Send

to Friend 7 1 GWEC reports that the country installed 483 MW in 2015,

helping to raise the installed capacity of the Africa and Middle East

region to nearly 3 300 MW. However, the story of 2015 was the surge

in Chinese installations, with an “astonishing” 30.5 GW added in

the year, raising the total global wind capacity installed last year

to 63 GW, a year-on-year market growth of 22%. China also moved past

the European Union (EU) as the leading wind market, with 145.1 GW

installed compared with the EU's 141.6 GW. “The Chinese

government's drive for clean energy, supported by continuous policy

improvement, is motivated by the need to reduce dependence on coal

which is the main source of the choking smog strangling China's major

cities, as well as growing concern over climate change,” GWEC said.

Total global capacity reached 432.4 GW at the end of 2015,

representing cumulative growth of 17%. "Wind power is leading

the charge in the transition away from fossil fuels,” GWEC

secretary-general Steve Sawyer enthused, adding that new markets were

opening up across Africa, Asia and Latin America. "2015 was a

big year for the big markets – China, the US, Germany and

Brazil, all set new records,” Sawyer added. "But there is a

lot of activity in new markets around the world and I think in 2016

we'll see a broader distribution.”

Vortex

generated electricity, Instead

of capturing

energy

via the circular

motion of a

propeller,

takes

advantage of what’s known as vorticity, an aerodynamic effect that

produces a pattern of spinning vortices. The Vortex’s shape was

developed computationally to ensure the spinning wind (vortices)

occurs synchronously along the entirety of the mast. In its current

prototype, the elongated cone is made from a composite of fibre

glass and carbon fibre,

which allows the mast to vibrate as much as possible (an increase in

mass reduces natural frequency). At the base of the cone are two

rings of repelling magnets, which act as a sort of non-electrical

motor. When the cone oscillates one way, the repelling magnets pull

it in the other direction, like a slight nudge to boost the mast’s

movement regardless of wind speed. This kinetic energy is then

converted into electricity via an alternator that multiplies the

frequency of the mast’s oscillation to improve the energy-gathering

efficiency. There

are no gears, bolts, or mechanically moving parts. It’s less

expensive to manufacture, totally silent, and safer for birds since

there are no blades to fly into. Its

turbine would cost around 51 percent less than a traditional turbine

whose major costs come from the blades and support system. It

is being developed by

Vortex

Bladeless.

Manufacturers

of wind turbine generators

- Siemens German manufacturer who became established with the creation of the world’s first offshore wind power plant in 1991 in Denmark. Siemens occupies a leading position within onshore wind power, having been awarded the world’s largest single onshore order to date,: a 1,050 MW order from MidAmerican Energy in the USA for a series of onshore wind power plants in Iowa.

- Sinovel Chinese manufacturer, who has manufactured more than 5 600MW of wind turbines in operation and is currently the 2nd largest turbine manufacturer in the world and holds a global market share of 11.1%

- Vestas Danish manufacturer started producing wind turbines in 1979 and have since gained a market-leading position with more than 64 GW of installed wind power and more than 42 GW under service globally.

- Honeywell The American Honeywell wind turbine is a gearless wind turbine that measures just 6 feet (1.8 m) in diameter, weighs 185 lbs (84 kgs) and produces up to 1500 kWh per year depending on height and location. It has a start-up speed as low as 0.5 mph (0.2 m/s), with an auto shut off at 38 mph (17.0 m/s), traditional gearbox turbines require minimum wind speeds of 7.5 mph (3.5 m/s) to cut in and start generating power.

- A Dutch renewable energy start-up called The Archimedes has a new class of small-scale wind turbine -- one that is almost silent and is far more efficient at converting wind into energy. The company states that the Liam F1 turbine could generate 1 500 kWh of energy per year at wind speeds of 5m/s, enough to cover half of an average household's energy use.

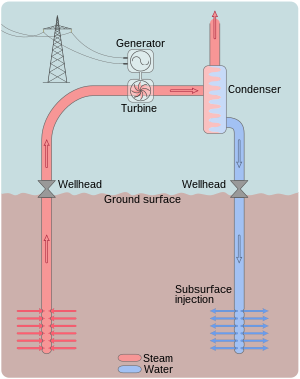

Geothermal electricity is electricity generated to geothermal energy. Technologies in use include dry steam power stations, flash steam power stations and binary cycle power stations. Dry steam stations are the simplest and oldest design. They directly use geothermal steam of 150°C or greater to turn turbines. Flash steam stations pull deep, high-pressure hot water into lower-pressure tanks and use the resulting flashed steam to drive turbines. They require fluid temperatures of at least 180°C, usually more. Geothermal electricity generation is currently used in 24 countries, while geothermal heating is in use in 70 countries.

As

of 2015, worldwide geothermal power capacity amounts to 12.8

gigawatts (GW),

of which 28 percent or 3,548 megawatts are installed in the United

States.

International markets grew at an average annual rate of 5 percent

over the last three years and global geothermal power capacity is

expected to reach 14.5–17.6 GW by 2020.

Based

on current geologic knowledge and technology, the Geothermal

Energy Association

(GEA)

estimates that only 6.5 percent of total global potential has been

tapped so far, while the IPCC

reported

geothermal power potential to be in the range of 35 GW to 2 TW.[2]

Countries

generating more than 15 percent of their electricity from geothermal

sources include El

Salvador,

Kenya,

the Philippines,

Iceland

and

Costa Rica.

Geothermal

power is considered to be a sustainable,

renewable

source

of energy because the heat extraction is small compared with the

Earth's heat content.

The

greenhouse

gas emissions

of

geothermal electric stations are on average 45 grams of carbon

dioxide

per

kilowatt-hour of electricity, or less than 5 percent of that of

conventional coal-fired plants.

Piezoelectricity

Piezoelectricity

is

the electric

charge

that

accumulates in certain solid materials (such as crystals,

certain ceramics,

and biological matter such as bone, DNA

and

various proteins)

in

response to applied mechanical stress.

The word piezoelectricity

means

electricity resulting from pressure. Piezoelectricity

is found in useful applications such as the production and detection

of sound, generation of high voltages, electronic frequency

generation, microbalances,

to drive an ultrasonic

nozzle,

and ultra fine focusing of optical assemblies. It is also the basis

of a number of scientific instrumental techniques with atomic

resolution, the scanning

probe microscopies

and

everyday uses such as acting as the ignition source for cigarette

lighters,

push-start propane

barbecues,

and quartz

watches.

Press

a lighter switch and you'll hear a clicking sound and see sparks

appear. What you're doing, when you press the switch, is squeezing a

piezoelectric crystal, generating a voltage, and making a spark fly

across a small gap.

Manufacturers

of piezoelectric materials and products

PI Ceramic GmbH has been developing and manufacturing piezo ceramic materials and components since 1992 for standard and OEM solutions: Piezo components, ultrasonic transducers, actuators and system solutions.

APC International Ltd. is a supplier of piezoelectric ceramic shapes, piezoelectric transducers, piezo devices, and piezo application support services. APC’s piezo products include: piezoelectric ceramics in standard and custom shapes, piezoelectric materials (PZT materials), stack actuators, ultrasonic air transducers, piezo nebulizers, piezo buzzers, piezo disc benders, bending actuators, piezo ignitors, ultrasonic cleaning transducers, piezo sensors, and custom transducers.

- Soundpower Corporation flagship product is the Power-Generating Floor,. While output varies depending on the number of tiles, a step by a person weighing 60 kilograms normally generates 0.1 Watt of power. In addition to its Power-Generating Floors, there are two other pillars to the company's operations: sound power and vibration power. Sound-power generation is a means by which the energy from speech and noise vibrations is turned into electricity. Soundpower is now at work developing various applications for this technology, including mobile phones that can be charged during conversations and sound-insulating walls that generate electricity from the sound of passing cars.

Goodyear tires, that use heat and vibration to recharge the battery, still a concept, would harvest heat from several different processes, and then feed that back into the batteries. At the core of the concept is a layer of piezoelectric material underneath the rubber of the tire. Piezoelectric materials can generate electricity from the application of mechanical force, but in this instance, the 'thermo-piezoelectric' material takes excess heat from the outside of the tire and converts it into electricity.

University

of Minnesota engineering researchers

recently

discovered a new alloy material, Ni45Co5Mn40Sn10,

that

converts heat directly into electricity. Researchers say the material

could potentially be used to capture waste heat from a car's exhaust

that would heat the material and produce electricity for charging the

battery in a hybrid car. Other possible future uses include capturing

rejected heat from industrial and power plants or temperature

differences in the ocean to create electricity. The

new material created by the researchers begins as a non-magnetic

material, which

then

becomes strongly magnetic when the temperature is raised a small

amount. When this happens, the material absorbs heat and

spontaneously produces electricity in a surrounding coil.

Static

electricity

Static

electricity is an imbalance of electric

charges

within

or on the surface of a material. The charge remains until it is able

to move away by means of an electric

current

or

electrical

discharge.

Static electricity is named in contrast with current

electricity,

which flows through wires or other conductors and transmits energy.

A

static electric charge is created whenever two surfaces contact and

separate, and at least one of the surfaces has a high resistance to

electrical current and is therefore an electrical

insulator.

A 40-year plan for energy

No comments:

Post a Comment