A

battery is a device that can store energy in a chemical form and

convert that stored chemical energy into electrical energy when

needed. There are no batteries that actually store electrical

energy; all batteries store energy in some other form. There are two

fundamental types of chemical storage batteries: the rechargeable, or

secondary cell, and the non-rechargeable, or primary cell. In terms

of storing energy or discharging electricity, they are similar, it

is simply a question of whether or not the chemical processes

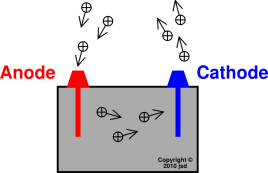

involved permit multiple charging and discharging. The

chemical reaction at the anode releases electrons and the reaction at

the cathode absorbs them. When the electrical path provided by the

electrolyte and an external electrical circuit connects the anode and

cathode, the two simultaneous reactions proceed and the electrons

freed at the anode travel through the external electrical connection

and react chemically at the cathode to make the cell function.

A

cathode

is

the electrode from which a conventional current leaves a polarized

electrical device. An

anode

is

an electrode through which electric current flows into a polarized

electrical device. An

electrolyte

is a substance that ionizes

when

dissolved in suitable ionizing solvents.

When

electrodes

are

placed in an electrolyte and a voltage

is

applied, the electrolyte will conduct electricity. Lone electrons

normally

cannot pass through the electrolyte; instead, a chemical reaction

occurs at the cathode,

consuming electrons from the anode.

Lead

acid batteries

Manufacturers

of lead acid batteries

EnerSys operates over twenty manufacturing and assembly plants in Europe, North America and Asia. EnerSys also provides aftermarket and customer support services to its customers from over 100 countries through its sales and manufacturing locations around the world.

South

Africa

- First National Battery is the leading lead acid battery manufacturer in South Africa, producing over 2.2 million batteries a year. Their batteries are used in more than 40 countries and the products cover various industries and applications ranging from mining, railway and renewable energy to surface traction, telecommunications and automotive (including industrial, commercial and passenger vehicles). First National Battery manufactures and distributes the industry-leading Raylite and Exide lead acid batteries. Batteries produced by First National Battery are the first choice among South African Original Equipment Manufacturers (OEMs) including Mercedes Benz, Toyota, Nissan, GM SA, BMW, Volkswagen SA, Renault, Ford, Nissan Diesel and MAN.

Dry

cell batteries

1. Brass cap

2.

Plastic seal

3.

Expansion space

4.

Porous cardboard

5.

Zinc can

6.

Carbon rod

7.

Chemical

mixture.

A

standard dry cell comprises a zinc

anode,

usually in the form of a cylindrical pot,

with a carbon

cathode

in

the form of a central rod. The electrolyte

is

ammonium

chloride

in

the form of a paste next to the zinc anode. The remaining space

between

the electrolyte and carbon cathode is taken up by a second paste

consisting of ammonium

chloride

and

manganese

dioxide,

the latter acting as a depolariser.

In some designs, the ammonium chloride is replaced by zinc

chloride.

Alkaline

batteries are

dependent upon the reaction between zinc

and

manganese

dioxide.

A rechargeable

alkaline battery

allows

reuse of specially designed cells. Compared with zinc-carbon

batteries

of

the

zinc chloride types, alkaline batteries have a higher energy

density

and

longer shelf-life,

with the same voltage. Button

cell

silver-oxide

batteries

have

higher energy density and capacity but also have a higher cost than

similar-size alkaline cells.

The

alkaline battery

gets its name because it has an alkaline

electrolyte

of potassium

hydroxide,

instead of the acidic ammonium

chloride

or

zinc

chloride

–manganese

dioxide

combination).A

dry cell uses a paste electrolyte,

with only enough moisture

to

allow current to flow. Unlike a wet

cell,

a dry cell can operate in any orientation without spilling, as it

contains no free liquid.

A

common dry cell is the zinc–carbon

battery

with

a nominal voltage of 1.5 volts,

the same as the alkaline

battery

(since

both use the same zinc

electrolyte

of the zinc-carbon batteries. Other battery systems also use alkaline

electrolytes, but they use different active materials for the

electrodes.

Lithium

batteries are

batteries

that

have lithium

metal

or lithium compounds as a anode.

They stand apart from other batteries in their high charge density

(long life) and high cost per unit. Depending on the design and

chemical compounds used, lithium cells can produce voltages from 1.5

V (comparable to a zinc–carbon

or

alkaline

battery)

to about 3.7 V. By comparison,

lithium-ion

batteries

are

rechargeable

batteries

in

which lithium ions move between the anode and the cathode, using

an

intercalated

lithium

compound

as

the electrode

material

instead of the metallic lithium used in lithium batteries.

South

Africa

- Eveready produces alkaline, lithium, zinc round cells , zinc layer cells and rechargeable cells under the brand names Eveready and Ecocell .

Lithium-ion

battery

A Lithium-ion battery (sometimes Li-ion battery or LIB) is a member of a family of rechargeable

battery

types

in which lithium

ions

move from the negative electrode to the positive electrode during

discharge and back when charging. Handheld

electronics mostly use LIBs based on lithium

cobalt oxide

(LiCoO2),

which offers high energy density, but presents safety risks,

especially when damaged.

Lithium

iron phosphate

(LFP),

lithium

manganese oxide

(LMO)

and

lithium nickel

manganese cobalt oxide (NMC) offer

lower energy density, but longer lives and inherent safety. According

to Frost & Sullivan, a leading growth-consulting firm, the global

market of rechargeable lithium-ion batteries is projected to be worth

US$23.4 billion in 2016.

- In June 2015, 24M Technologies Inc claimed that they will reduce Li-ion battery costs to 50% of today’s costs with their semi-solid lithium ion battery and that it could also fundamentally change the entire cost structure of the industry. Lithium-ion battery cells typically use graphite for the anode. Manufacturers have looked into the benefit of using silicon for the anode because silicon can hold a lot more lithium ions.

- Researchers at MIT and Samsung, and in California and Maryland, have developed a new approach to one of the three basic components of batteries, the electrolyte. The new findings are based on the idea that a solid electrolyte, rather than the liquid used in today’s most common rechargeables, could greatly improve both device lifetime and safety — while providing a significant boost in the amount of power stored in a given space.

- Scientists at Nanyang Technology University (NTU) have developed ultra-fast charging batteries that can be recharged up to 70 per cent in only two minutes. The new generation batteries also have a long lifespan of over 20 years, more than 10 times compared to existing lithium-ion batteries. In the new NTU-developed battery, the traditional graphite used for the anode (negative pole) in lithium-ion batteries is replaced with a new gel material made from titanium dioxide.

Manufacturers

of lithium-ion batteries

A123

Systems, LLC develops and manufactures advanced

Nanophosphate® lithium

iron phosphate batteries ( at the cell, module and system level,)

and energy storage systems (ESS). A123 Systems' head

quarter is in Livonia, Michigan and employs more than 2,000 people

worldwide. A123 has more than 1 million square feet of manufacturing

facilities in Asia, Europe and North America.

Altairnano

is the first company to replace traditional graphite materials used

in conventional lithium-ion batteries with a proprietary,

nanostructured lithium-titanate. PowerRack is a complete industrial

battery system for commercial use and fully scalable to 40 modules

Johnson

Matthey Battery Systems (formerly Axeon) is Europe’s largest

independent Lithium-ion battery systems supplier, processing over 70

million cells a year and supplying volume production of batteries for

global markets. The

UK

operation focuses on the design and manufacture of large-scale high

voltage automotive grade battery systems for Electric and Hybrid

Electric vehicles and batteries for mobile power products. In Poland

they

design

and manufacture high performance battery packs for the professional

cordless power tools and electric bike markets.

BYD

Company Limited (BYD) is a listed company on Hong Kong Stock Exchange

and

Shenzhen

Stock Exchange, specialized in IT, automobile and new energy

industries. BYD has nearly 180,000 employees and 12 industrial parks

located in Shenzhen, Beijing, Xian, Shanghai, Changsha and other

cities across China with an area over 15,000,000 square meters. BYD

has formed a global network including branches or offices in United

States, Europe, Japan, India, Hong Kong, Taiwan, etc.

Electrovaya

designs, develops and manufactures proprietary Lithium Ion

SuperPolymer® 2.0 batteries, battery systems, and battery-related

products for the transportation, grid power, consumer and

healthcare markets.

LG

Chem produces cathode materials, electrolytes, and separators which

are core materials of rechargeable batteries. In addition to mobile

batteries used in various IT devices, they are also producing mid to

large battery materials for electric cars and energy storage systems.

Mitsubishi

Heavy Industries, Ltd. (MHI) has concluded an agreement with Delta

Electronics, Inc., a leading manufacturer of electronic devices

in Taiwan, under which MHI will sell Delta its business assets,

including machinery, in lithium-ion rechargeable batteries. As a

result MHI will shift its management resources into operations in

energy storage system (ESS) products employing lithium-ion

rechargeable batteries.

Development,

manufacturing and sales of NiMH batteries for PEV/HEV; lithium-ion

batteries and BMS (Battery Management System)

Powerwall

comes in 10 kWh weekly cycle and 7 kWh daily cycle

models. Both are guaranteed for ten years and are sufficient to

power most homes during peak evening hours. Multiple batteries may be

installed together for homes with greater energy need, up to 90 kWh

total for the 10 kWh battery and 63 kWh total for the 7 kWh battery.

Tesla's

Gigafactory will eventually have an annual production capacity

of 35,000,000 kWh, or 35 GWh.

For

home use a 2.5 kWh capacity unit with a maximum of 8 modules. They

also manufacture units for commercial and industrial companies.

Produces

a semi-solid

lithium-ion battery that

speeds

up

production

and reduces lithium-ion battery costs by 50%.

- StoreDot

StoreDot's FlashBattery technology relies on "nanodots", which are comprised of bio-organic peptides whose raw materials are abundant in nature and also self-assemble, making for a more affordable product. These form the basis of a multi-function electrode that allows for supercapacitor-like rapid charging, with a slow discharge more like a lithium-ion battery. The concept still includes lithium components in the cathode, but the company claims that its modified anode and cathode and a proprietary electrolyte and separator are responsible for the incredible recharge speeds.

Graphene and batteries

Graphene can make batteries that are light, durable and suitable for high capacity energy storage, as well as shorten charging times. It will extend the battery’s life-time, which is negatively linked to the amount of carbon that is coated on the material or added to electrodes to achieve conductivity, and graphene adds conductivity without requiring the amounts of carbon that are used in conventional batteries. Graphene can improve such battery attributes as energy density and form in various ways. Li-ion batteries can be enhanced by introducing graphene to the battery’s anode and capitalizing on the material’s conductivity and large surface area traits to achieve morphological optimization and performance.

Commercial Graphene-enhanced battery products

Electric

vehicle batteries

An

electric

vehicle battery (EVB)

or traction

battery is

a battery used to power the propulsion of a battery

electric vehicles

(BEVs).

Rechargeable

batteries are usually the most expensive component of BEVs, being

about half the retail cost of the car. Since the late 1990s, advances

in battery technologies have been driven by demand for laptop

computers and mobile phones, with consumer demand for more features,

larger, brighter displays, and longer battery time driving research

and development

in

the field. The BEV marketplace has reaped the benefits of these

advances, but costs remain too high and, along with limited range,

provide a key barrier to the use of rechargeable batteries in

electric vehicles. The cost of electric vehicle batteries has been

reduced by more than 35% since 2008. Rechargeable traction batteries

are routinely used all day, and fast–charged all night. Forklifts,

for instance, are usually discharged and recharged every 24 hours of

the work week. The predicted market for automobile traction batteries

is over $37 billion in 2020.

On

an energy basis, the price of electricity to run an EV is a small

fraction of the cost of liquid fuel needed to produce an equivalent

amount of energy (energy

efficiency).

The cost of replacing the batteries dominates the operating costs.

Vehicle

|

Battery

|

Chevy

Volt

|

16.5

kWh

|

Nissan

Leaf

|

24

kWh

|

Chevy

Bolt

|

60

kWh

|

Tesla

Model S

|

70

kWh / 85 kWh

|

Liquid metal batteries

Initially based on magnesium and antimony as the negative and positive electrodes, respectively, and a low cost molten salt electrolyte, but transitioned to using a higher voltage and lower cost chemistry. All three active components are in liquid form when the battery operates. The two liquid electrodes are separated by a molten salt electrolyte, and these liquid layers float on top of each other based on density differences and immiscibility. The system operates at elevated temperature maintained by self-heating during charging and discharging. The result is a low-cost and long lifespan storage system.

Vanadium redox Flow Batteries

Connventional

technologies for the chemical storage of electricity (e.g.

electrolyzer, methanation, fuel cells) show a relatively low

efficiency. Redox Flow Batteries (RFB), however, show a DC-efficiency

of up to 80% – depending on the system and consideration – which

is within the range of efficiencies of conventional secondary

batteries (lithium-ion, lead or nickel-metal-hydride batteries). In

contrast to conventional battery systems in which power and storage

capacity are interrelated, Redox Flow Batteries have the ability to

scale power and storage capacity independently of each other.

Basically the RFB can cover a storage requirement of several hours to

a few days.

Capacitor

storage

A

capacitor

(originally

known as a condenser)

is a passive

two-terminal

electrical

component

used

to store energy

electrostatically

in

an electric

field.

The forms of practical capacitors vary widely, but all contain at

least two electrical

conductors

(plates)

separated by a dielectric

(i.e.

insulator).

A

capacitor

can store electric energy when disconnected from its charging

circuit, so it can be used like a temporary

battery,

or like other types of rechargeable

energy storage system.

Capacitors

are commonly used in electronic devices to maintain power supply

while batteries are being changed. Conventional

capacitors provide less than 360 joules

per

kilogram of energy

density,

whereas a conventional alkaline

battery

has

a density of 590 kJ/kg. In car

audio

systems,

large capacitors store energy for the amplifier

to

use on demand.

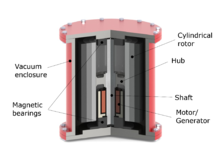

Flywheel energy storage

Flywheel

energy storage (FES)

works

by accelerating a rotor (flywheel)

to a very high speed and maintaining the energy in the system as

rotational

energy.

When energy is extracted from the system, the flywheel's rotational

speed is reduced as a consequence of the principle of conservation

of energy;

adding energy to the system correspondingly results in an increase in

the speed of the flywheel. Most

FES systems use electricity to accelerate and decelerate the

flywheel, but devices that directly use mechanical

energy

are

being developed. Since FES can be used to absorb or release

electrical energy such devices may sometimes be incorrectly and

confusingly described as either mechanical

or

inertia

batteries.

Advanced

FES systems have rotors made of high strength carbon fiber

composites, suspended by magnetic

bearings,

and spinning at speeds from 20,000 to over 50,000 rpm in a vacuum

enclosure.

Such

flywheels can come up to speed in a matter of minutes – reaching

their energy capacity much more quickly than some other forms of

storage.

Uninterruptible

power supply

An

uninterruptible

power supply,

also uninterruptible

power source,

(UPS)

or

battery/flywheel

backup,

is an electrical apparatus that provides emergency power to a load

when the input power source, typically mains

power,

fails. A UPS differs from an auxiliary or emergency

power system

or

standby

generator

in

that it will provide near-instantaneous protection from input power

interruptions, by supplying energy stored in batteries,

supercapacitors,

or flywheels.

The on-battery runtime of most uninterruptible power sources is

relatively short (only a few minutes) but sufficient to start a

standby power source or properly shut down the protected equipment.

An

UPS is typically used to protect hardware such as computers,

data

centers,

telecommunication

equipment

or other electrical equipment where an unexpected power disruption

could cause injuries, fatalities, serious business disruption or data

loss. UPS units range in size from units designed to protect a single

computer

without

a video monitor (around 200 volt-ampere

rating)

to large units powering entire data centers or buildings. The world's

largest UPS, the 46-megawatt Battery Electric Storage System (BESS),

in Fairbanks,

Alaska,

powers the entire city a

Using nature to grow batteries

Using nature to grow batteries

.png)

No comments:

Post a Comment